In today’s hyper-related international, electromagnetic interference (EMI) isn’t always simply an inconvenience—it’s an actual chance to the overall performance and protection of cutting-edge electronics. Yet, a few manufacturers still gamble with outdated materials which can’t maintain up with nowadays’s demands. That’s in which defensive tape modifications the game. Designed for sturdiness, conductivity, and precision, it provides engineers and innovators with precisely what they want: dependable safety for gadgets that strengthen our daily lives.

Why Relying on Outdated Materials Is a Costly Mistake

Here’s the debatable component—many organizations nevertheless assume conventional tapes and coatings can “do the job.” But allow’s be sincere—they are able to. Conventional substances destroy beneath warmth, lose adhesion, and fail to dam interference efficiently. The reality is harsh: an unmarried vulnerable point in defense can disrupt conversation structures, harm circuit forums, and compromise entire projects.

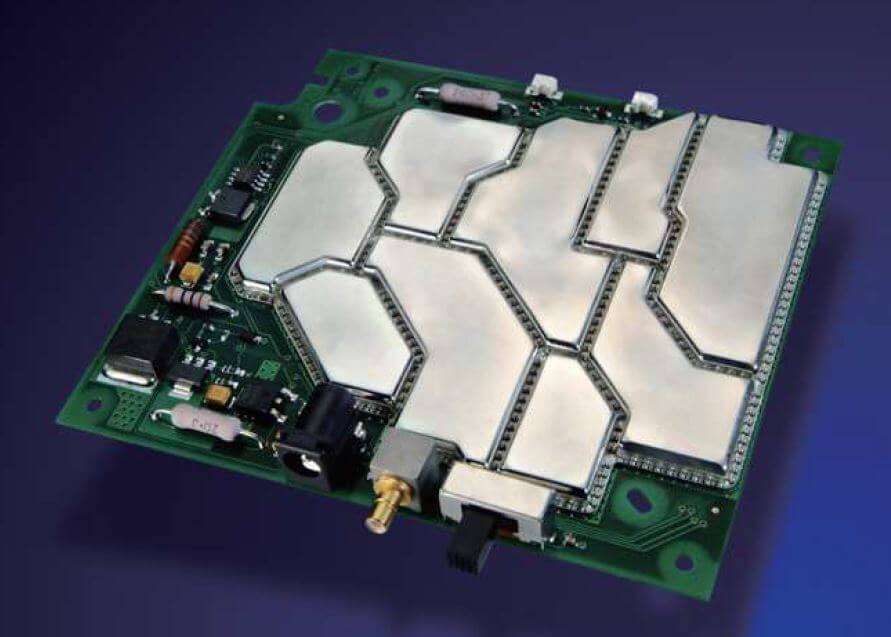

This is why forward-questioning industries are moving toward advanced materials that pair seamlessly with strategies like vacuum metallization. Together, shielding tape and vacuum metallization form a protecting framework this is light-weight, conductive, and constructed for the future. Unlike outdated methods, this aggregate doesn’t just meet industry standards—it exceeds them.

The Power of Metallized PET Film in Electronics

If there’s one material that embodies performance and innovation, it’s metallized PET film. Known for its fantastic reflective residences and barrier overall performance, this film is extensively used in electronics insulation, packaging, and shielding casings. Its versatility and strength make it the pass-to desire for engineers looking to balance overall performance, value-effectiveness, and sustainability.

When metallized PET movie is mixed with protective tape, the end result is an extremely-reliable barrier that blocks interference whilst maintaining flexibility and sturdiness. And when more advantageous through vacuum metallizing, this gadget presents unmatched resistance towards environmental factors such as warmth, humidity, and UV exposure.

Vacuum Metallizing: A Breakthrough for Modern Devices

The reality? Old-faculty coating methods are not just inefficient—they’re conserving industries lower back. Vacuum metallizing represents the future of electronics manufacturing. By depositing thin layers of steel onto a substrate beneath vacuum situations, this technique delivers surfaces which are uniform, reflective, and notably strong.

For electronics, this indicates higher protection, lightweight answers, and higher design flexibility. When paired with protecting tape, vacuum metallizing offers devices the durability they need to face up to interference, environmental pressure, and the demands of high-performance programs.

Applications That Prove Shielding Tape Is Indispensable

Shielding tape isn’t only for experts—it’s being used across an extensive variety of industries in which overall performance cannot be compromised.

- Consumer Electronics – Smartphones, laptops, and wearables all rely upon EMI protecting characteristics well.

- Aerospace and Defense – High-reliability components need light-weight, conductive protection.

- Automotive – With EVs and clever motors, protecting tapes ensure protection and connectivity.

- Medical Devices – Life-saving equipment demands wonderful EMI safety.

- Telecommunications – Networking and communique infrastructure depend on interference-loose indicators.

Each application underscores one truth: without shielding tape, the dangers always outweigh the expenses of prevention.

Why Speed and Reliability Matter

Let’s be real—delays in manufacturing can spoil momentum. Fast-paced industries can’t wait weeks for essential substances. That’s why experts consider providers who can deliver shielding tape quickly and reliably. Fast delivery means engineers live on schedule, producers keep away from downtime, and projects circulate forward without interruptions.

And let’s no longer overlook this: reliability isn’t pretty much quick delivery, it’s additionally approximately constant product performance. Shielding tape has earned its reputation among experts because it plays beneath pressure, over and over.

Sustainability Meets Performance

A growing challenge for plenty of companies is the environmental footprint in their operations. Shielding tapes, metallized PET Film, and vacuum metallizing all make a contribution to greener answers. They reduce fabric waste, reduce energy intake, and provide recyclable options—all even as retaining the overall performance ranges industries call for.

This stability of sustainability and durability is exactly what today’s marketplace seems for, making shielding tape and funding no longer most effective in performance but also in long-time period responsibility.

Final Thoughts: The Smarter Choice for Modern Electronics

Electronics are evolving at a breakneck pace, and the substances supporting them should keep up. With the blended strength of protective tape, vacuum metallization, metallized PET Film, and vacuum metallizing, corporations can stable gadgets towards interference, extend product lifespan, and meet developing needs for efficiency and sustainability.